The Difference Between Adapter and Withdrawal Sleeves

What Are Adapter Sleeves?

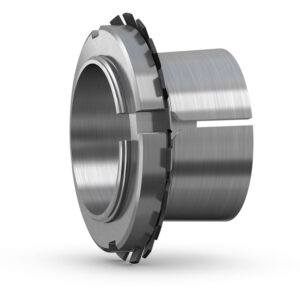

Adapter sleeves are essential for mounting bearings with a tapered bore onto straight shafts. These cylindrical components feature a tapered outer surface and a straight inner bore that matches the shaft's diameter. The sleeve provides a secure fit for the bearing and shaft without compromising on the bearing’s weight-bearing capacity with axial loads. As the sleeve is driven onto the shaft and into the bearing's tapered bore, it expands marginally. This expansion creates a strong, frictional grip that effectively controls the bearing during use

For precise installation and positioning, most adapter sleeves are equipped with a thread and locknut system at one end. This system enables the locknut to push against the bearing's inner ring, forcing it up the sleeve's taper until the ideal, secure fit is achieved.

Order from Bearing Depot today for quality materials in various dimensions for reliable parts for your projects.

What Are Withdrawal Sleeves?

Unlike adapter sleeves, withdrawal sleeves are specifically engineered for straightforward bearing dismounting. A notable feature of withdrawal sleeves is their threaded end, which extends beyond the bearing. This unique design provides ample space for dismounting tools, greatly simplifying the removal process and preventing potential damage to both the shaft and the bearing. Their design offers a clear advantage in scenarios where bearings need to be replaced or maintained regularly.

Minimise your downtime and improve productivity with our withdrawal sleeve range. Including the brands DIV and SKF for dependable parts. Order online with Bearing Depot for a simple purchase and delivery experience.

Applications of Adapter & Withdrawal Sleeves

The difference in product is simplified down to the mounting and removal of the sleeve.

-Adapter sleeves are placed in line with the bearings, whereas withdrawal sleeves are mounted on the opposite side.

-To apply an adapter sleeve, you may need a nut and some form of puller; however, withdrawal sleeves are simpler to remove.

-You might want to opt for a withdrawal sleeve where applications require more regular replacements and maintenance for ease of use.

Choosing The Right Sleeve For Your Applications: Adapter Sleeves or Withdrawal Sleeves?

Adapter and Withdrawal sleeves are made with quality, strong materials that mean their performance and lifespan are dependable; they’re machined with precision and are ideal for manufacturing. Choosing the right sleeve depends on several considerations:

- Shaft Design and Dimensions

- Load Conditions

- Space Constraints

- Operating Environment

- Maintenance and Serviceability

For more permanent installations, choosing the adapter sleeve may be the way forward in place with nuts for locking their position. The best choice ultimately depends on your project's unique needs. Think about any space limitations, how simple the assembly needs to be, and the overall complexity of your application.

At Bearing Depot, our knowledgeable team are here to advise on the best products for your projects and help you find the right sizes. Don’t hesitate to reach out to us for assistance in ordering your adapter or withdrawal sleeves.

How Can Bearing Depot Help?

Seek Product Support

Looking for more information about our products or have any questions? Submit our contact form and one of our specialists will be in touch with you as soon as possible.

Alternatively, you can:

Call us at

01952 676925

Email us at

sales@bearingdepot.co.uk